Hella launches new solutions for thermal management of electric vehicles

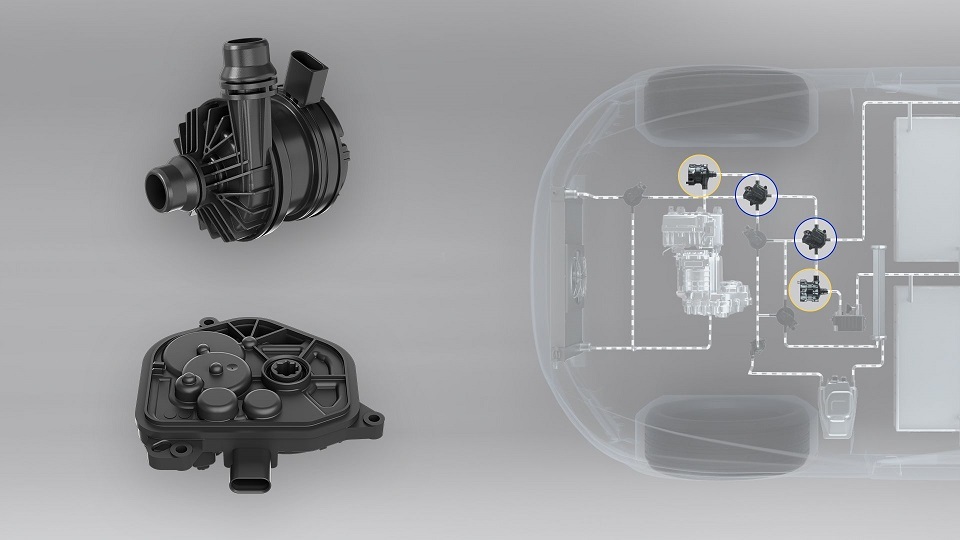

Hella, the automotive supplier operating under the FORVIA umbrella brand, is expanding its existing thermal management portfolio with an electronic Valve Actuator and a high-performance Media Pump for coolant circulation.

Hella has now started series development of these new, high-performance components; market launch has been scheduled for 2025.

The thermal management system controls the respective heat flows in the vehicle. This ensures that parts and components, such as engines or batteries can be operated within their ideal temperature range and that the vehicle interior can be air-conditioned according to individual needs.

“Sophisticated thermal management is an indispensable part of modern vehicle architectures. Above all, the trend towards electromobility is leading to a further increase in demand for corresponding product solutions,” says Björn Twiehaus, Hella Management Board member responsible for the global electronics business. “Our thermal management portfolio is already broad and includes numerous actuators, valves, pumps, and system solutions. We are now launching two new components to further advance the electrification of mobility.”

As pivotal components of an efficient thermal management system, Hella’s electronic Valve Actuator as well as the high-performance Media Pump ensure that coolant is directed through the coolant circuit of an electric vehicle as required. This ensures optimal temperature control of all critical components, for example battery and power electronics. Consequently, it is possible to increase the service life and efficiency of the lithium-ion battery, as well as boost the overall ranges of electric vehicles.

In the cooling circuit, the coolant is circulated by the high-performance Media Pump (MPX). With the start of production in North America, Europe and China, the pump will be available in the new 300 and 400 watt power categories to take into account the different requirements of the cooling circuit and vehicle architecture. It addresses the requirements of electric vehicles and can thus improve the performance, service life and safety of the high-voltage battery.

The electronic Valve Actuator (eVA) is responsible for controlling the multi-way valve that distributes the coolant in the cooling circuit. In this process, the actuator opens and closes the respective inputs and outputs of the valve, whereby the temperature of the coolant can also be controlled with a mixing function. The electronic Valve Actuator operates with a brushless motor and can therefore meet the high demands in terms of service life, efficiency and performance of future electric vehicles. eVA is available in two different torque categories and has been cost-optimised based on its modular platform approach.