Bosch invests 6 million euros in metal 3D printing center

With a new metal 3D printer at its Nuremberg plant, Bosch wants to bolster its pioneering role in the supplier industry. In fact, it is the first Tier-1 automotive supplier in Europe to have a facility in this performance class. The plant has invested almost six million euros in the center and in the associated purchase and installation of a Nikon SLM Solutions NXG XII 600 metal 3D printer.

“Bosch remains committed to Germany as an industrial location and is investing large sums of money here. By introducing new technologies in our plants, we are securing considerable sales potential,” says Klaus Mäder, the member of the Bosch Mobility sector board responsible for operations, including all plants worldwide. The new 3D printer is intended to accelerate development cycles, especially for metal parts, which take a long time to make using conventional manufacturing processes. Commenting on the facility’s official start of operations, Alexander Weichsel, the commercial plant manager in Nuremberg, says: “By making the manufacture of metal parts faster and more productive, this new facility will increase our competitiveness.” And the technical plant manager Jörg Luntz adds: “With this facility, we are setting the highest standards in metal 3D printing. In volume production, this will open up completely new possibilities for us.”

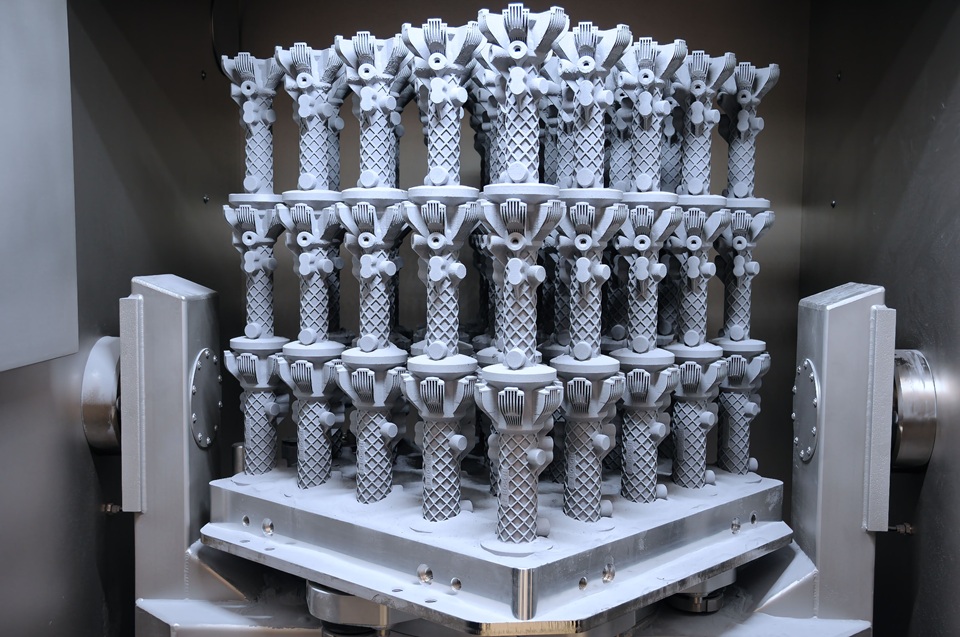

Whether components for hydrogen applications, motor housings for electric cars, components for e-axles, or engine blocks for racing: the facility’s sheer size and technical capabilities pave the way for a host of applications. Working from a computer-aided design file developed in advance, its twelve lasers melt metal powder layer by layer to create highly complex shapes. The new metal 3D printer is up to five times faster than the 3D printing systems that have been used up to now. Complex structures such as interior or curved channels, which are simply not feasible with conventional milling processes, can now be produced without any problem. While drilling around corners is not possible using conventional methods, 3D printing makes light work of this. The printer can produce unfinished parts on demand with no need for tooling. And because 3D printing slashes raw-material waste to almost zero, it also conserves resources. “Using the 3D printer to manufacture components not only increases sustainability in production, but also enables Bosch to respond flexibly to fluctuations in batch sizes and offer everything from a single source,” Weichsel says.

One particularly vivid example of the new possibilities that the 3D printing process opens up is the engine block: with conventional manufacturing, it can take up to three years to get from the first draft design to volume production. Completing the casting mold for the engine block alone can take up to 18 months. 3D printing does away with this step. The design data is transmitted directly to the printer, eliminating the need for complex molds. The 3D printer delivers a finished engine block after just a few days, thus greatly reducing overall product development time.

At full capacity, the facility can produce metal parts with a total weight of around 10,000 kilograms in under a year, achieving speeds of up to 1,000 cubic centimeters per hour. The main aim of this faster component production is to cut the time to market. “We want to be faster than with traditional manufacturing processes and use this technology to get products to market more quickly,” Luntz says. “Even today, only a few companies can produce technology on an industrial scale the way Bosch does. We’re now going one step further, taking volume production in metal 3D printing to the automotive level.” This opens the door to completely new opportunities and possibilities – in the automotive sector, but also in numerous other industries such as energy and aviation.