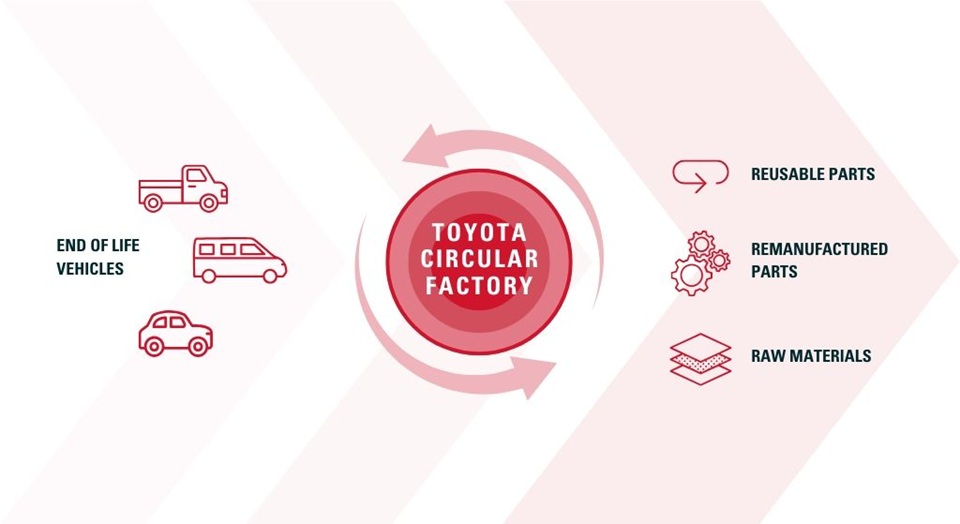

Toyota launches Circular Factory to maximise recycling and recovery from end-of-life vehicles

Toyota Motor Europe has announced the establishment of Toyota Circular Factory to process vehicles at the end of their life to maximise the environmental benefits of re-cycling, re-purposing and re-manufacturing.

The first operation, located at Toyota Motor Manufacturing UK (TMUK)’s Burnaston plant, will begin activities in the third quarter of this year, and aims to become the centre of excellence for future recycling operations across Europe and worldwide. This initiative will be implemented alongside TMUK Burnaston site’s principal activity of producing Toyota Corolla vehicles.

Toyota Circular Factory is the name given to TME’s overall recycling activities, and it is structuring its approach to end-of-life vehicle processing around three key areas: re-usable parts, commodity items that can be re-manufactured and materials that can be recycled.

Following a comprehensive validation process, re-usable parts will be reintroduced into the market through retailers or parts distributors. Commodity items such as batteries and wheels will be assessed for their potential to be re-manufactured, re-purposed, or recycled.

Finally, Toyota intends to recycle raw materials such as copper, aluminium, steel, and plastic. These recycled materials would then replace virgin materials as much as possible in the production of new parts for new vehicles.

“We initially anticipate recycling around 10,000 vehicles a year in our UK facility, which will give new life to 120,000 parts, recover 300 tonnes of high purity plastic and 8,200 tonnes of steel – amongst other materials. As a next step for the Toyota Circular Factory concept, we plan to roll out similar operations across Europe. And we’re not stopping at our own facilities – we are eager to collaborate with other organisations who share our passion of circularity and commitment to carbon neutrality,” said Leon van der Merwe, Vice President of Circular Economy at Toyota Motor Europe.