ZF launches a new generation of its range extender technology, with production to start in 2026

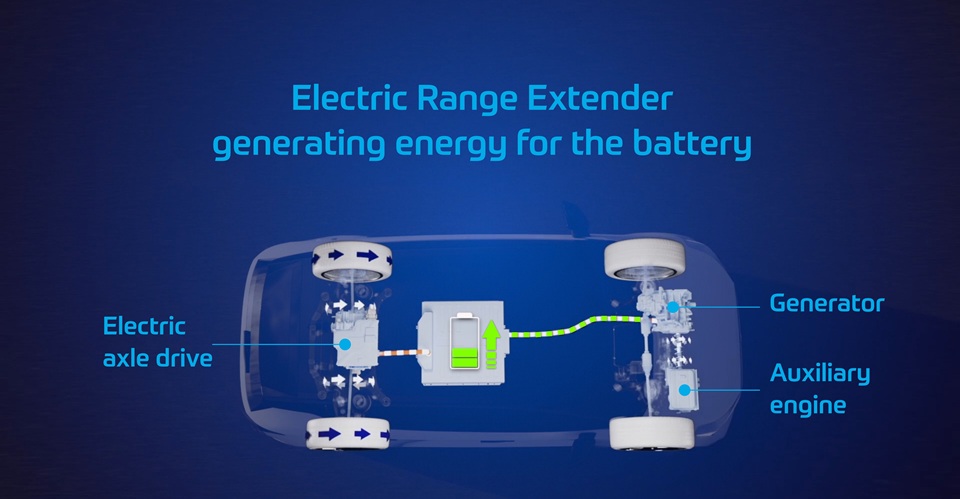

Many potential buyers of electric vehicles still feel the so-called range anxiety that accompanies all-electric driving. In these cases, range extenders can be one solution: A combustion-powered generator that is coupled to an electric motor and thus generates energy for the vehicle battery. ZF is now introducing its new generation of this technology, which will go into volume production in 2026.

“Although the all-electric range of passenger cars is around 500 km on average, range anxiety still influences a wide range of buyers when choosing their next vehicle,” explains Otmar Scharrer, Senior Vice President R&D, Electrified Powertrain Technology. This is especially true in regions where a charging infrastructure is not yet universally available. ZF is currently developing the next generation of range extenders for these situations. “These represent a real alternative to larger – and thus more expensive – batteries or plug-in hybrids,” says Scharrer.

With range extenders, a combustion-powered engine is coupled to an electric motor that generates power for the vehicle battery as soon as its state of charge drops below a certain threshold. As the name implies, this increases the range that can be driven electrically. A further advantage over PHEVs or conventional combustion engines is that the range extender unit always operates in the ideal performance range for fuel consumption and lower CO2 emissions.

ZF already has range extender technology in volume production and amongst other vehicles, it was installed in the iconic London taxi. ZF is currently working on the next generation, with the electric Range Extender (eRE) and the electric Range Extender plus (eRE+).

“The new interest and the increased demand for range extenders shows that the potential of this technology is far from exhausted – in particular for model platforms that are already designed for battery-electric drivelines,” says Scharrer while adding: “Behind our solutions is a system and platform concept. This means that we are optimally equipped to be able to respond to all customer and market requirements with shorter development cycles.”

Compared to parallel-hybrid drive solutions, for example a PHEV, range extenders are compelling due to their lower additional costs, shorter development cycles, reduced platform integration effort and simplified supply chain management. This makes technology particularly interesting for manufacturers who are new to the market and may have little experience with traditional combustion engine drivelines.

China is currently embarking on a model offensive with so-called “Range Extended Electric Vehicles” (REEV), which, thanks to the technology, can cover distances of more than 700 kilometres. “This is where we find it convenient that there is a wide range of BEV platforms that can be supplemented by range extenders,” explains Scharrer.

However, the interest of manufacturers is also increasing in the USA and Europe. “The market for all-electric vehicles has not developed as much as predicted a few years ago,” says Scharrer. “For this intermediate phase, range extenders can be the ideal solution.”

REEV drivers can enjoy the advantages of electromobility without having to sacrifice the flexibility of PHEVs or combustion engine passenger cars. Range extenders are also of interest to traditional manufacturers. They allow smaller (and therefore more economical) vehicle batteries to be installed and help to comply with emission limit values for fleets.