Bosch supplies factory equipment for battery production, aims for sales of 250 million Euro by 2025

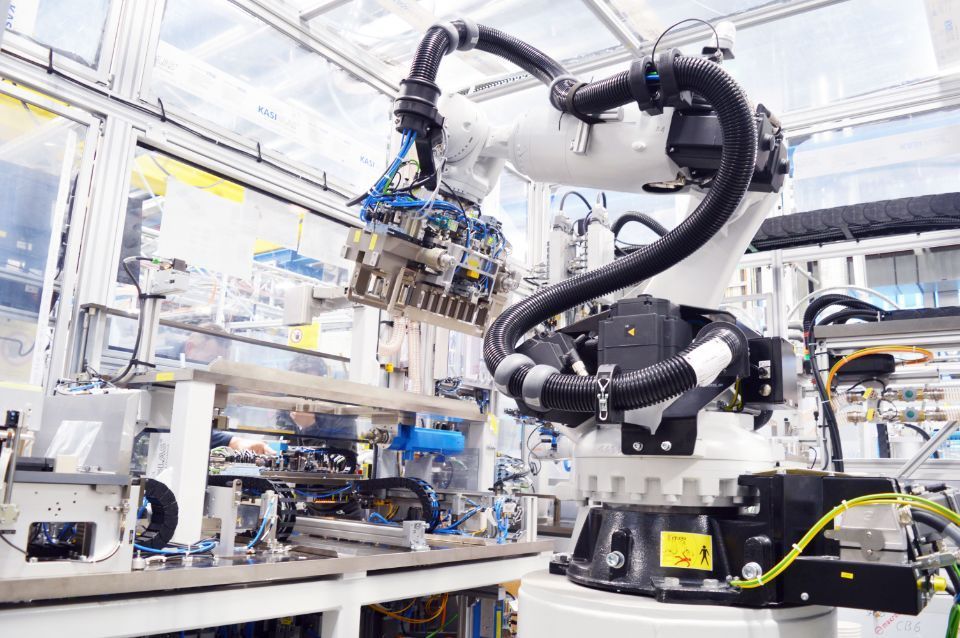

Bosch is pooling its mechanical engineering expertise and offering companies factory equipment for battery production from a single source – ranging from individual components and software solutions to complete assembly lines.

One of its pilot customers is Webasto, which is equipping its battery factories with Bosch technology. “We know batteries like the back of our hand, as well as how they have to be manufactured,” says Rolf Najork, the member of the Bosch board of management responsible for industrial technology. In entering this business, Bosch aims to increase vertical integration in mechanical engineering and, by 2025, to generate annual sales of some 250 million euros with equipment for battery production. Bosch also uses its production know-how in its own plants: at its plant in Eisenach, Germany, Bosch is now launching full-scale production of second-generation 48-volt batteries. The company is investing some 70 million euros this year in expanding local manufacturing operations.

The market is huge: experts predict that demand for lithium-ion batteries will rise from around 200 GWh in 2019 to more than 2,000 GWh by 2030 (source: BMWi, 2021). Currently, more than 60 percent of that demand stems from electromobility (source: VDMA, 2020). Bosch offers a portfolio of solutions ranging from 48-volt mild hybridization to fully electric drives and fuel cells. The company has experience in developing batteries for vehicles as well as for e-bikes, power tools, and kitchen appliances, and has extensive manufacturing expertise. Bosch intends to use this know-how to meet the growing demand.

Webasto is a pioneer in the production of battery packs. The company has been involved in the field of electromobility since 2016 and, in addition to high-voltage heaters and recharging solutions, also focuses on battery systems for electrified vehicles. Battery production at Webasto’s plant in Schierling, Germany, serves as a blueprint for new production facilities like the one in Dangjin, Korea. Bosch’s role is to supply automated assembly lines for welding and gluing the battery cells. For this purpose, the various functions of module production are combined: cell cleaning with incoming inspection, the stacking process as well as a special laser-welding process, and end-of-line inspection for quality assurance. Thanks to a sophisticated line concept, no particle contamination occurs during processing. Robots automatically assemble the cell stacks in a two-step procedure consisting of dispensing technology and laser welding. With a comprehensive safety concept, it is then possible to establish the battery module’s electrical connection using a highly dynamic and precise laser-welding process.