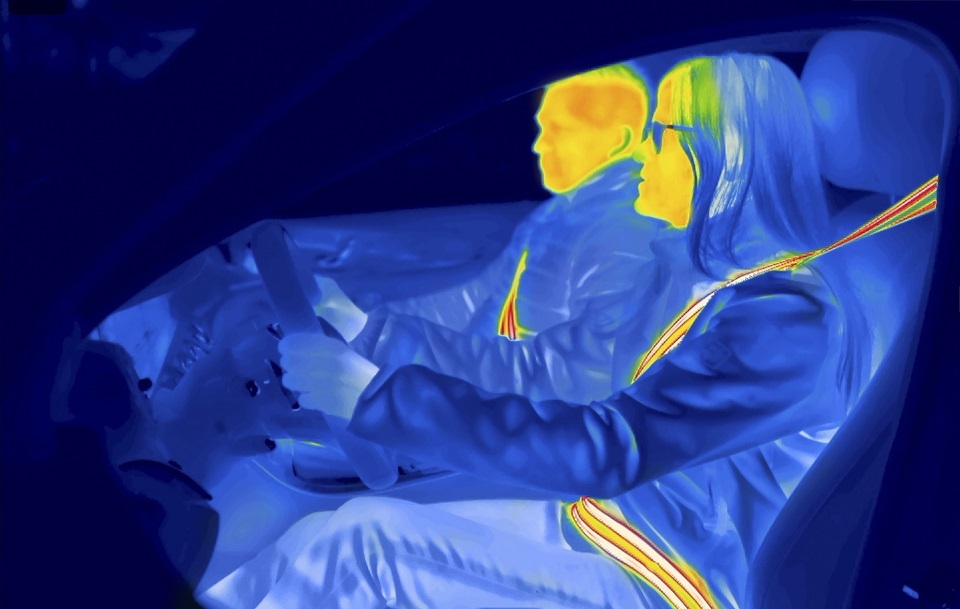

ZF’s new ‘heat belt’ can help improve energy efficiency of electric vehicles in cold weather

ZF has developed a heated seat belt option for electric vehicles. This technology allows drivers to reduce the energy used to heat the vehicle — especially in combination with other contact heaters such as a seat heater. During cold weather, the system may increase range by up to 15 percent by reducing the energy required to heat the interior of the vehicle.

The ZF heated seat belt is based on a special webbing with integrated heating conductors that minimally increase the thickness of the webbing. This makes integration easier for vehicle manufacturers and offers occupants the same comfort as normal seat belt webbing. The heated belt is designed to provide occupants with a uniform feeling of warmth close to the body.

With this integrated heating function, ZF’s new heated seat belt can provide close-to-body warmth immediately after the driver starts driving, typically between 36 and 40 degrees Celsius. In combination with heated seats, the heated seat belt has the potential to provide occupant comfort quickly. In electric vehicles, the climate control system is powered by battery current, as there is no usable waste heat as with the combustion engine. Reducing the amount of battery current used to

heat the interior of the vehicle may enable a range gain of up to 15 percent using contact heaters and reducing the usage of conventional climate control systems.

ZF used a special textile processing method for this innovation. The heating conductors are woven into the seat belt structure. The contact elements for the electrical heating circuits are positioned in such a way that they do not interfere with belt operation or retraction. Special belt retractors at other installation positions are not necessary.