Mercedes-Benz starts using AI and humanoid robots at German factory

Mercedes-Benz is accelerating the transformation of its production network by using Artificial Intelligence (AI) and humanoid robots at its Berlin-Marienfelde factory in Germany.

In 2022, Berlin-Marienfelde established itself as the global centre of competence for the digitalisation of production with the Mercedes Benz Digital Factory Campus (MBDFC), promoting the development of future software applications in a real production environment.

The central basis of the activities is the Mercedes-Benz Cars Operations 360 digital production ecosystem, or MO360, which contains all the important software applications and data of the global production network.

Mercedes-Benz has now enhanced its MO360 production system with AI features like the Digital Factory Chatbot Ecosystem and the MO360LLM Suite, and with humanoid robots from U.S.-based company Apptronik, reinforcing Berlin-Marienfelde’s status as a centre for global innovation.

Today, new production processes and features including those enabled through the Mercedes-Benz Operating System (MB.OS) are tested before they are sent to real-life production lines at other Mercedes-Benz assembly plants.

“Mercedes-Benz Berlin-Marienfelde remains at the cutting edge of automotive production and keeps Germany on the map as a global centre for innovation. Artificial Intelligence and humanoid robots open up an exciting new frontier which make automotive production more sustainable, efficient and more intelligent.” – Jörg Burzer, Member of the Board of Management of Mercedes-Benz Group AG, responsible for Production, Quality & Supply Chain Management

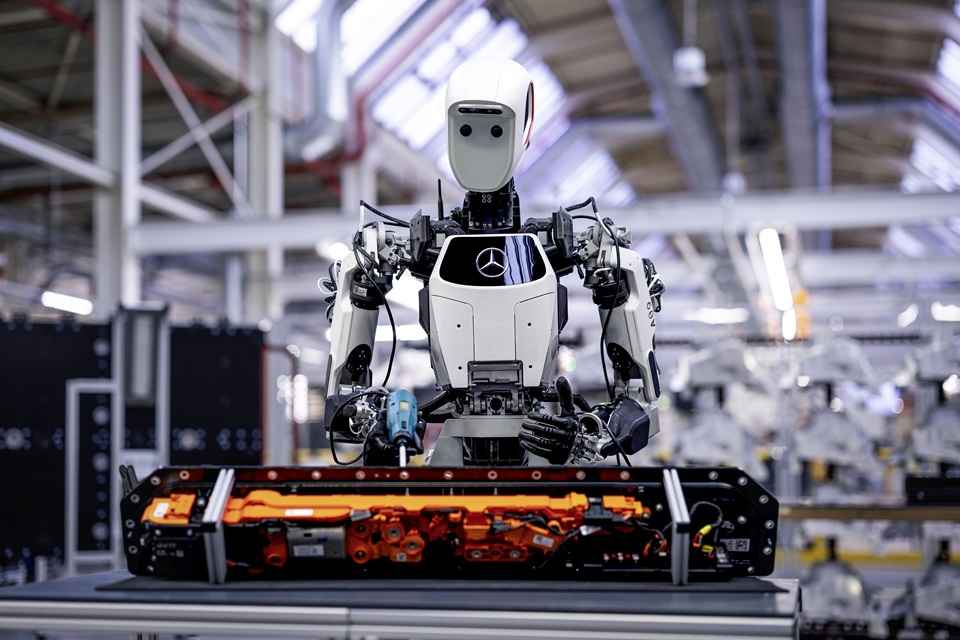

Mercedes-Benz is committed to empowering its staff with state-of-the-art technology – and with Apollo, Mercedes-Benz brings one of world’s most advanced commercial humanoid robots into its manufacturing facilities. To underscore its commitment to deploying humanoid robots in automotive production, Mercedes-Benz will make a low double-digit-million-euro investment into Apptronik, which was founded in 2016 at the Human Centered Robotics Lab at the University of Texas at Austin.

Mercedes-Benz has been using industrial robotics technology since the 1970s to perform particularly monotonous and physically demanding tasks. Mercedes-Benz is currently testing the integration of humanoid robots in production with an initial focus on repetitive tasks within intralogistics.

Apptronik’s Apollo can be used to transport components or modules to the production line for Mercedes-Benz’s highly skilled production staff to assemble, and to carry out initial quality checks of components.